The influence of coating material characteristics on coating effect

In the coating process,the characteristics of the coating material have a crucial impact on the coating effect.

Firstly,the hardness of the coating material determines the surface hardness after coating.If the coating material itself has a high hardness,the resulting film layer will also have a high hardness,which can better resist scratching and wear.For example,in some application scenarios that require high wear resistance,such as tool coating,choosing coating materials with high hardness can significantly improve the service life and cutting performance of the tool.On the contrary,if the hardness of the coating material is low,the film layer may be easily scratched,thereby affecting the appearance and performance of the product.

Secondly,the chemical stability of the coating material will affect the corrosion resistance of the coating.Coating materials with good chemical stability can protect substrate materials from corrosion in various harsh environments.For example,in the chemical industry,equipment surfaces often need to be coated with materials with high chemical stability to prevent corrosion by chemical substances.If the chemical stability of the coating material is poor,the film layer may undergo a chemical reaction and be damaged when in contact with specific chemicals,losing its protective effect.

The optical properties of coating materials also have a significant impact on the coating effect.Different coating materials have different optical parameters such as refractive index and transmittance.By selecting appropriate coating materials,specific optical effects such as anti reflection,anti glare,etc.can be achieved.For example,in the coating of optical instruments and eyeglass lenses,selecting coating materials with specific optical characteristics according to different needs can improve the clarity and visual effect of the lenses.

In addition,the thermal stability of the coating material is also crucial.For products applied in high-temperature environments,it is necessary to choose coating materials with good thermal stability to ensure that the film layer will not deform,peel off,or experience performance degradation at high temperatures.If the thermal stability of the coating material is poor,under high temperature,the film layer may have problems such as cracks and bubbles,which will affect the performance of the product.

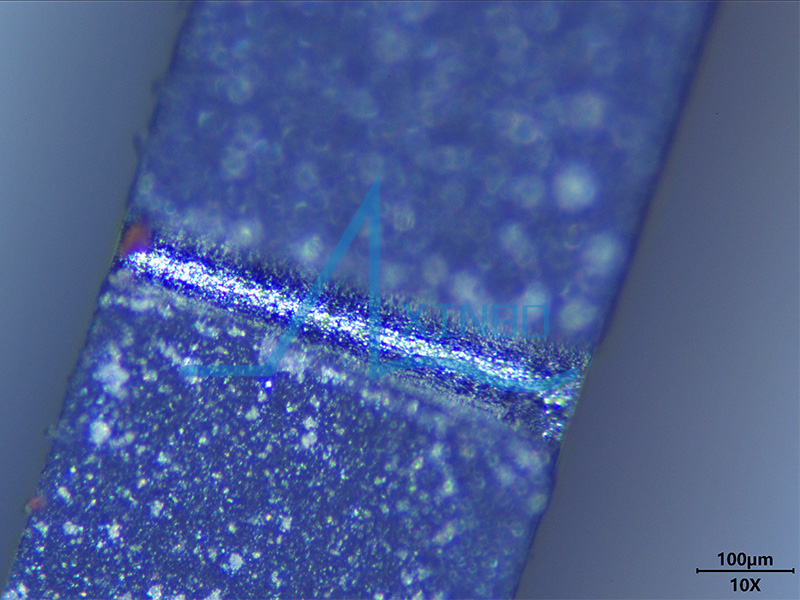

The adhesion of coating materials is also an important factor.If the adhesion between the coating material and the substrate material is strong,the film layer can firmly adhere to the substrate and is not easily detached.On the contrary,if the adhesion is poor,the film layer may gradually peel off during use,reducing the effectiveness and service life of the coating.

In summary,the characteristics of coating materials,including hardness,chemical stability,optical properties,thermal stability,and adhesion,will have a specific and important impact on the coating effect.When selecting coating materials,fully consider these characteristics to meet the needs of different application scenarios.

0769-81001639

0769-81001639